Industrial safety system

Safety solutions for industrial refrigeration installations

Our technological solutions for industrial safety systems in refrigerated facilities respond to modern industry’s different needs. They protects workers from any risk arising from their work activity, but also focus on guaranteeing the integrity of the assets of that system, in addition to the stored product.

For AKO, this safety is incredibly important; in order to guarantee it, our technicians have studied the current regulations of each country thoroughly and rigorously and have tailored our solutions to them, so that the degree of satisfaction of each of our customers is as high as it possibly can be.

Why opt for an industrial safety system?

Our connected solutions enable the user to be automatically alerted, remotely and from any part of the world in a simple and convenient way.

We offer you devices with connectivity, indicators and alarm notifications, via email or via relay activations and integration with CRA systems, to enable a fast action in the event of a fault, accident or setback with your cold room.

This is always in accordance with the strict compliance of current safety and environmental regulations and standards:

RD552/2019 | EN 378:2016 | CE37/2005 | ITC 3701/2006 | EN-12830 | ICT-155:2020 F-Gas

All of our products are designed to meet the regulations and legislation in force in each country in the strictest sense. This is, without a shadow of a doubt, the best guarantee for all of our customers.

Our technicians and engineers have developed state-of-the-art solutions that enable you to guarantee the integrity of your system at all times, as well as the people in it. They also safeguard the products that you have stored, so you will have complete peace of mind and be in full control.

With our solutions, safety and technology go hand in hand

We have various industrial safety systems for refrigerated facilities, a factor that enables us to fully adapt to the needs of each of them without any problems:

Temperature and humidity monitoring

RD-552/2019, in IF11, sections 4ª, 4b, and 4c, states:

Cold rooms of more than 10 m³:

A. In cold rooms with deep-frozen products (-18 °C), a temperature recorder subjected to metrological control must be installed.

B. In other cold rooms, a temperature recorder must be installed (in these cases, the law does not specify that this recorder must be subjected to metrological control).

C. In refrigerated cold rooms, a hygrometer must also be installed when the product stored is not hermetically packaged.

Cold rooms of less than 10 m³:

D. A thermometer subjected to metrological control must be installed, and the reading must be recorded at least twice a day.

SOLUTION:

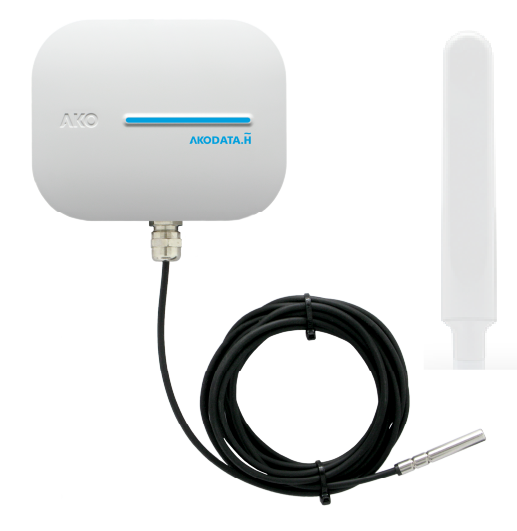

- AKODATA STANDARD for cases B and C.

- AKODATA.H for case A and as an alternative to case D.

- DARWIN.H for case D.

Gas detection alarms

RD-552/2019, in IF16, section 3.1, and in IF01, section 3.2.9, it states:

Cold rooms of more than 10 m³:

A. A gas detector must be installed when these cold rooms exceed the practical permitted limit, as stated in EN-378.

B. This gas detector must be equipped with alarm relays to activate a siren or similar.

C. It should also be equipped with a sound and visual alarm.

Cold rooms of less than 10 m³:

D. Cold rooms with an interior volume of less than 10 m³, are not required to have a detector.

Engine rooms and workrooms:

E. A gas detector must be installed for every 50 m², whenever the following situations apply:

- The Practical Limit is exceeded

- There is more than 25 kg of gas (of any gas with PCA > 0)

- 25% of the LFL (Lower Flammable Limit) is exceeded.

- 50% of the ATEL/ODL (Oxygen Deprivation Limit) is exceeded.

SOLUTION:

- AKOGAS or AKOSECURE for cases A, B and C.

- AKOGAS for case E.

Trapped person alarms

RD-552/2019, in IF12, section 3.3.1 states:

Cold rooms that operate between 0 and 5 °C:

A. A Trapped Person Alarm without a battery must be installed

Cold rooms that work below 0 °C, or with an artificial atmosphere:

B. A trapped person alarm without a battery must be installed and another with a battery.

C. The battery operated alarm must have a minimum life of 10 hours in alarm state.

D. In both cases, the push buttons must be installed at a maximum height of 1.25 m and next to the cold room door. In addition, the push buttons must be lighted to make them easier to locate.

SOLUTION:

AKOALAM or AKOSECURE for cases A, B and C.

PRODUCTS

AKOALARM

AKOGAS NDIR

AKOGAS

AKOSECURE

Temperature and humidity monitoring solution.

AKODATA

_